Powder Coatings for the Oil and Gas Industry:

Advanced Protection in Harsh Environments

The oil and gas industry operates in some of the most challenging environments on the planet, from offshore rigs exposed to saltwater to pipelines in extreme temperatures. In such demanding conditions, the right protective coatings are essential to ensure the longevity and performance of equipment and infrastructure. Powder coatings, especially those enhanced with cutting-edge nanoparticle technology, offer superior protection against corrosion, high temperatures, and chemical exposure.

Corrosion Resistance: Guarding Against Deterioration

Corrosion is a major concern in the oil and gas sector, where metals are exposed to moisture, salt, and corrosive chemicals. Standard coatings often fail to provide long-term protection in such harsh conditions. Powder coatings, however, form a durable barrier that resists the penetration of corrosive elements. Our advanced formulations, such as Cubson’s Graphecoat, incorporate graphene and other nanoparticles to further enhance corrosion resistance. These particles create a tightly bonded, impenetrable layer that significantly slows down the degradation of metals, protecting pipelines, storage tanks, and offshore equipment.

High-Temperature Stability: Performance in Extreme Conditions

Oil and gas operations frequently involve high-temperature environments, whether it’s in deep drilling or refinery processes. Powder coatings designed for the industry must withstand these extreme temperatures without breaking down or losing their protective qualities. Our high-performance coatings are formulated to endure thermal stress, ensuring that critical components, such as valves, pumps, and heat exchangers, maintain their integrity and performance in temperatures that can reach hundreds of degrees Celsius.

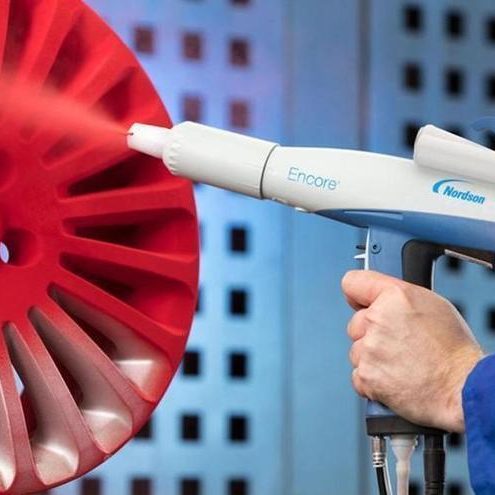

Nanoparticles: The Future of Coatings Technology

One of the most exciting developments in powder coating technology for the oil and gas industry is the integration of nanoparticles. These ultra-fine particles, including graphene, significantly enhance the mechanical properties of the coating. By improving adhesion, hardness, and resistance to wear, nanoparticle-enhanced coatings provide a longer-lasting, more durable solution. In highly abrasive environments, such as drilling operations, these coatings protect equipment from wear and extend the service life of expensive machinery.

Key Applications in Oil and Gas

Pipelines

Coatings protect pipelines from corrosion, abrasion, and harsh environmental conditions, ensuring the safe and efficient transport of oil and gas.

Offshore Platforms

Exposed to saltwater, wind, and UV radiation, offshore structures benefit from the corrosion-resistant and UV-stable properties of powder coatings.

Storage Tanks

Both above-ground and underground storage tanks need coatings that resist chemical corrosion and protect against leaks and environmental contamination.

Valves and Fittings

Precision parts in oil and gas equipment require coatings that not only protect against corrosion but also enhance durability under constant use and pressure.

Long-Term Protection and Sustainability

At Cubson, our powder coatings for the oil and gas sector offer a sustainable and efficient solution, eliminating the need for frequent maintenance and recoating. By incorporating nanoparticle technology, we ensure that our coatings provide long-term protection against corrosion, temperature extremes, and chemical exposure, helping to reduce downtime and extend the lifespan of critical infrastructure.

CUBSON INTERNATIONAL CONSULTING

POWDER COATINGS FOR DIFFERENT INDUSTRIES.

Avenida Flores, 19 (PQUE EMPRESARIAL EL MOLINO)

28970 Humanes, Madrid

OPENING HOURS

MONDAY TO FRIDAY

9:00 am - 6:00 pm

SATURDAY-SUNDAY

CLOSED

______________________________________

Necesitamos su consentimiento para cargar las traducciones

Utilizamos un servicio de terceros para traducir el contenido del sitio web que puede recopilar datos sobre su actividad. Por favor revise los detalles en la política de privacidad y acepte el servicio para ver las traducciones.